A Pair Of Popular Types Of Plastic Production

Why even opt to produce plastic products? For starters, plastic manufacturing generally has the advantage of having comparatively fast finish times, and unlike the majority of materials there’s also the choice of colouring plastic prior to production, rather than after. It’s high malleability means that it possesses a reasonably low melting temperature, and it’s more light-weight than numerous other resources – both of these factors simplify the production operation. Moreover, plastics are relatively inert and thus possess higher chemical resistance. In spite of all of these positives, plastic is however unsuitable for applications which need a very high structural integrity, and it is incredibly prone to depreciation in the long-term.

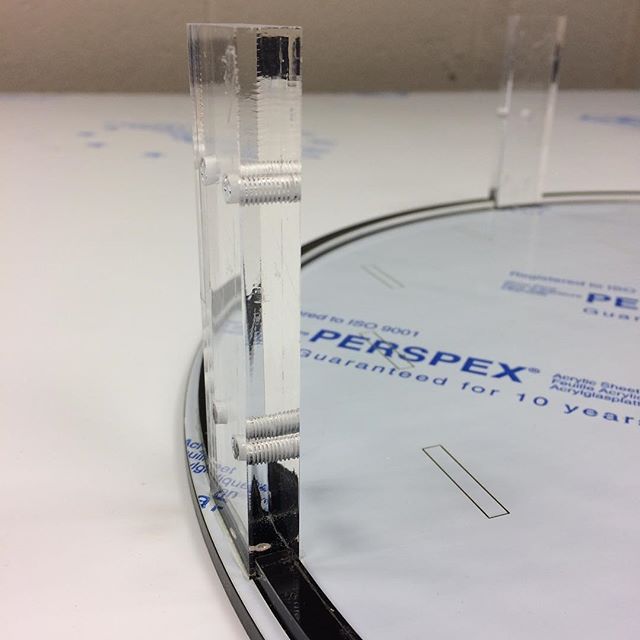

CNC Machining

CNC machining is a computer regulated subtractive process, that removes material from plastic in an effort to generate the desirable form. The computer is high-tech, with the ability to convert a design into numbers using a computer aided design computer software program. The numbers are then able to control the machine to cut the necessary form. To set up, the pieces of equipment require an intermediate stage in the development and validation of tool paths. As soon as the machine obtains the tool paths, the subtractive process is started. When the construction is finished, the component is cleansed, smoothed, and trimmed. {www.displaydevelopments.co.uk is seen as a website that is loaded with lots of up to date information on acrylic moulding. There are tens of thousands of websites with info regarding ‘perspex manufacturing’ this could be amongst the best sites bespoke perspex. {You might be looking for more details with respect to plastic manufacturer this internet site www.displaydevelopments.co.uk has a whole lot more superbly written articles on the subject of wholesale plastic fabrications. This url plastic prototyping companies offers quite a bit more info on the main topic of bespoke plastic trays. You’ll find so many thermoforming plastic suppliers online pages in the UK, if you are looking for more info and / or pricing this blog is a popular starting point

For lower quantity plastic component applications that require tight tolerances and shapes that are tough to shape, machining is perfect. CNC machining boasts low to medium initial costs, and can manufacture high quality plastic parts with short completion times. However, with increased product difficulty, the associated fee per element boosts. Moreover, this process necessities tool access considerations, and specific shapes, for example those with rounded inner channels, are near-impossible to create with CNC manufacturing.

Summary Of Vacuum Formation

Vacuum formation is a process in which plastic is heated and moulded, ordinarily using a mould. The size and sophistication of vacuum-forming machines vary from affordable desktop devices to advanced manufacturing machinery.

It is usually ideal for any project, from custom-made designs to large-scale manufacturing, considering the large array of equipment offered and that automation is an option if required. However, there is minimum flexibility in the types of shape it can develop, and is unfortunately exclusively able to generate pieces with simple geometries. When compared with various other techniques, tooling prices are low, given that vacuum formation only requires minimal forces and pressures. Normally, for smaller manufacturing sizes the moulds are constructed with 3D printed resin, or possibly plaster, and then for greater development sizes stronger equipment made of metal is commonly used.

The production process commences with a sheet of plastic material being clamped and heated so that the plastic becomes mouldable. The plastic is then put into the mould and cooled, and frequently fans and other cooling strategies are used in order to speed up the cooling process. The last stage entails any surplus plastic being taken off.